The use of water to dilute enzymes for Post-Pelleting Application (PPLA) is a common and desirable practice. At the design stage of the circuit, and during its use, certain points relating to the quality of the water must be monitored to ensure the correct application of the enzymes, the preservation of their quality and that of the feed produced.

The manufacturing process of compound feed is mainly a dry process. However, water is sometimes added in liquid form in the mixer and systematically in the form of steam during the pelleting process. In addition to the process, water can be used to clean certain surfaces and trucks.

In the case of liquid enzymes, water can be used as a carrier or diluent to increase the amount of solution sprayed to optimize the homogeneous distribution in the feed.

The addition of water can be avoided (and therefore pure enzyme solutions can be sprayed at 100 or 200 ml per ton) when the installation is particularly well designed and maintained for low doses application. Let’s say that the addition of water is an additional guarantee.

This water addition has no other impact on the quality of the feed because it is a small amount. There is no significant change in moisture or water activity.

In practice, the enzymatic solution(s) (1, 2 or 3) are supplemented with water to reach a total quantity of 1 liter of solution per ton.

This dilution must really be mixed, and you must not be satisfied with the common arrival of 2 sections of pipe upstream of the nozzles.

But let’s go back one step: pumps, whether for water or for enzymatic solutions, must meet at least these two criteria:

The most common and safest source is mains water which is potable and requires little or no treatment.

In some areas, mains water may not be safe to drink and will require treatment.

Another source is well water. Its microbiological quality will depend on the depth at which it is drawn but contamination by surface water is always possible.

Depending on the origin and quality of the water, particularly in the case of well water, several successive types of treatment can be implemented. We will pass on the screening/straining, flocculation and sedimentation phases which are done in the water treatment plants.

Filtration:

the most common filtering media is sand and gravel, but granular activated carbon is the media of choice because it not only provides excellent mechanical filtration of particulate matter, but also removes organic compounds which can cause taste and odor problems.

Disinfection:

to destroy potential remaining bacteria and viruses. The most common process is chlorination. Several sources of chlorine are possible but the most convenient is the addition of bleach (sodium hypochlorite – NaClO). For this step, it is rarer to use ozonation or ultraviolet light.

Demineralization:

depending on the hardness of the water, i.e. its mineral concentration, it may be advisable to soften it to prevent scaling of the installations. A common method for water softening involves the use of ion-exchange resins, which replace ions like Ca2+ by twice the number of mono cations such as sodium or potassium ions.

There are different standards in the world for drinking water. One of these standards is that of France, where water may not contain more than 0.2 mg/L of chlorine at most. The European Union has also adopted a chlorine concentration in drinking water of no more than 0.1 mg/L since December 22, 2013.

The World Health Organization (WHO) recommends keeping chlorine levels at no more than 0.5 mg/L to ensure the safety of drinking water.

When the water comes from the drinking water network, this guarantee alone is sufficient to qualify the water for all possible uses in a feed plant.

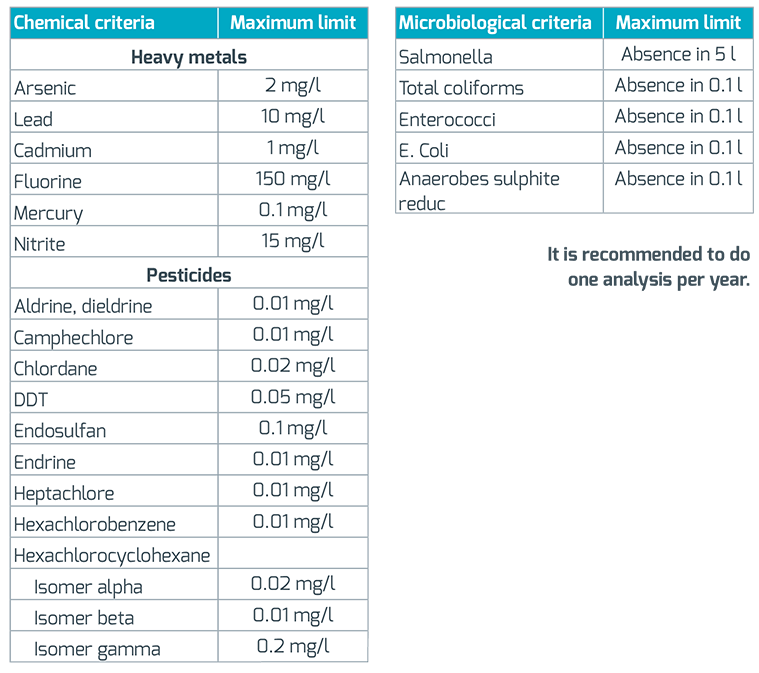

When this is not the case, the manufacturer will have to control the criteria such as: the concentration of heavy metals, pesticides, and microbiological quality at annual frequency.

In the absence of a local reference, one can refer to the Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed (heavy metals and pesticides), and to the Directive 98/83/EC on the quality of water intended for human consumption (microbiological parameters).

Beyond the question of safety, other criteria can be questioned regarding enzyme dilution:

Three main factors of contamination may affect water quality and have an impact on the quality of use of enzymes:

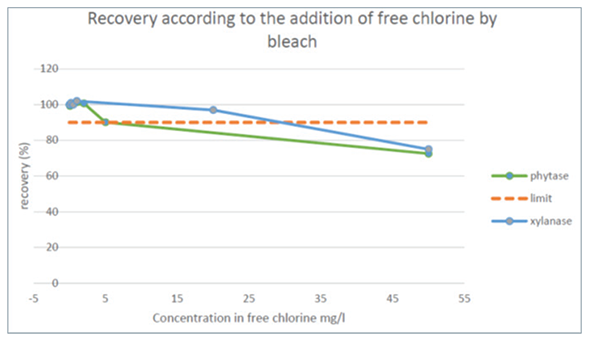

This study tested concentrations well beyond the maximum recommended values (to simulate drift or error).

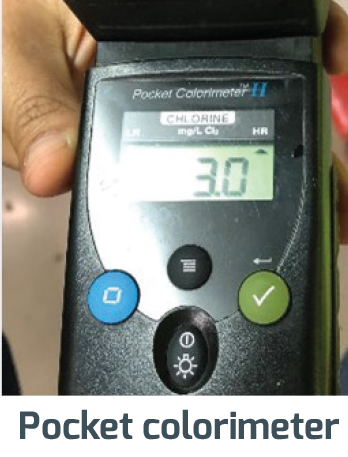

To avoid problems with chlorination of the water, check the chlorine concentration regularly (monthly for instance).

The presence of surfactant in the circuits is very unlikely but could occur in the following cases: cleaning of circuits without subsequent rinsing, common transfer circuits with a surfactant (for addition in the mixer), or lubricant leakage (on a transfer pump for example).

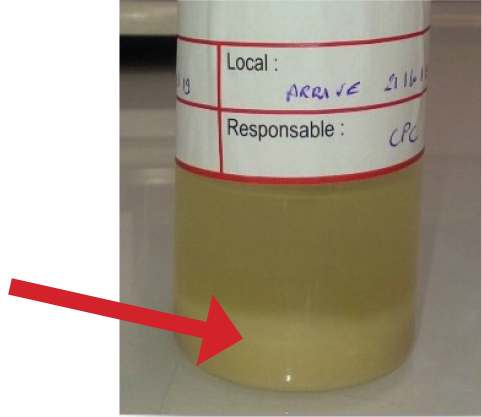

The risk is low but could occur at the level of the water tank, especially if it is partially or totally open and therefore exposed to the dust from the plant, and especially if there is no chlorination.

One should therefore be vigilant on this point and possibly plan an annual emptying and disinfection.