The safety and quality of feed materials, such as grain, is a high-profile topic of great importance. Grain is an important and significant source of contamination in the food chain and it also carries the risk of the consumers being exposed to toxins. As grain storage is an integral part of the food and feed supply chain, the storage operations of grain should include the control of any potential hazards (insects, molds, mycotoxins etc.) which could compromise the safety and quality of feeds.

The control of these hazards during grain storage operations is normally a part of any good storage practices (GSP). GSP measures can include: 1) reducing the risk through biosecurity or prevention of the hazard from arriving on-site; 2) conducting point-in-time controls, such as thermal processing during pelleting or irradiating feeds and feed materials during processing and 3) using preservatives in the feeds and feed materials to provide protection.Molds can grow over a wide range of temperatures and, in general, the mold growth rate decreases as the temperature and water availability decrease. Generally speaking, the higher the moisture content is, the more susceptible the grain to mold deterioration. Molds in grains utilize inter-granular water vapor (free water).

Temperature has a direct effect on the mold growth rate and the formation of mycotoxins. It has been reported that the higher the temperature is, the greater the rate of growth and the higher the level of produced mycotoxins. The optimum temperature for Aspergillus growth and aflatoxin production is 24 – 35°C. Aspergillus can also grow at lower temperatures, but at a slower rate. Penicillium molds also grow faster at higher temperatures with the optimum temperature for growth and toxin formation being 18 – 32°C. However, other economically important species of molds, such as Fusarium, can grow rapidly at lower temperatures (4-15°C) and produce toxins at lower temperatures than 15°C.

Penicillium Aspergillus

Several strategies can be adopted to control the growth and development of molds, and hence reduce their effects on the quality of feeds and feed material, and on animal performance. An important strategy is an appropriate storage, whereby many of the problems can be alleviated if the feeds and feed material are stored in clean and well-ventilated silos. A second way of controlling molds and any further accumulation of mycotoxins is the use of chemicals, such as mold inhibitors. Preventing the loss of feeds and feed material quality from molds and pests during storage is easier, safer and less expensive than resorting to curative programs to improve spoiled feeds and feed materials. The aim of an effective feed and feed material storage procedure is to avoid quality losses from the time they are stored until the time they are used. For this purpose, it is important to keep the mold contamination as low as possible.

A practical and widely used method to control mold in stored feeds and feed material is through the Treatment Program for Feed and Feed Material developed by Adisseo. This Program, with Mold-Nil®, has been developed and approved for the safe storage and management of the feed material used in animal feeds. It contributes to the production of a hygienically safe food supply for the consumer.

Mold-Nil®, which is available in both liquid and dry forms, is uniquely formulated with a synergistic buffered blend of organic acids for the effective inhibition of molds. The use of Mold-Nil® is a well-established practice for preserving feeds and feed materials from mold growth, whereby the nutritive value is stabilized and safe-handling is ensured throughout long-term storage.

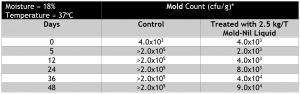

A challenge trial was carried out to study the efficacy of Mold-Nil Liquid in preserving corn to which 18% moisture was added over a storage period of 48 days. Table 1 shows that Mold-Nil Liquid worked effectively in inhibiting the mold growth, despite a higher moisture content in the corn.

Table 1. Challenge trial to evaluate the efficacy of Mold-Nil Liquid in preserving corn with a high moisture content of 18%

*Molds: >2.0×105, Low quality: 1.0×105 – 2.0×105, Acceptable quality: 1.0×104 – 1.0×105 and High quality: <3.0×104

The Mold-Nil Liquid formulation has been is optimized and buffered to have an almost-neutral pH for safe handling without corrosion of the silos and equipment.

The quality of feeds and feed material is determined by its composition and its microbiological load. The number of mold spores is in particular an important factor. Little can be done about mold contamination and the subsequent production of toxins in the field before grain is harvested. However, a mold Inhibition Program, implemented after the grain is harvested, combined with correct storage practices is the key to minimizing post-harvest mold growth and mycotoxin production.